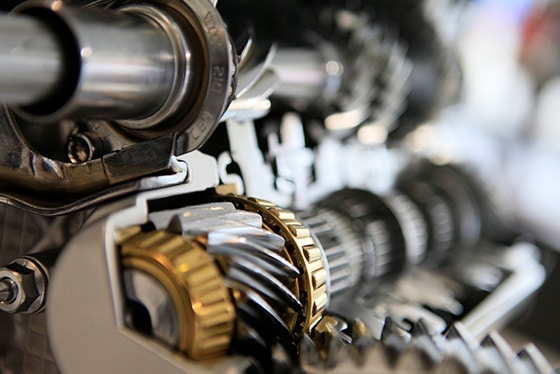

We respond to our customers' various needs with a focus on forged steel products from Pacific Steel Mfg. Co., Ltd., which has more than 80 years of manufacturing history.

The forged steel products handled by our company have been adopted as important parts in various fields such as power plant, steel, ships, paper Mills and industrial machinery.

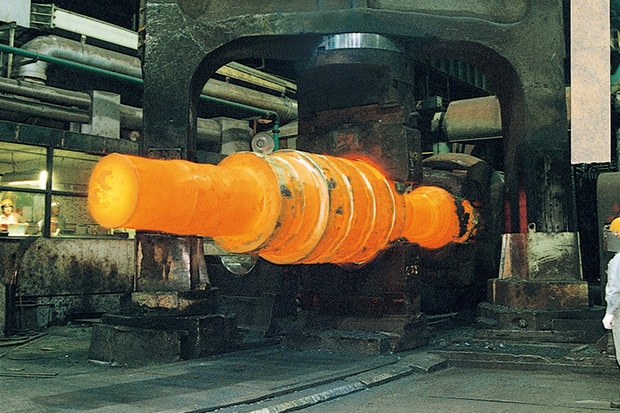

Pacific Steel Mfg. Co., Ltd., a part of our group companies, has a 4,300-ton and an 8,000-ton forged press, and can consistently produce forged steel products featuring free forging from steel manufacturing to machining. Furthermore, forged cast iron rolls for hot rolling (NT-ROLL), developed based on unique ideas, have been widely adopted by domestic and overseas steel manufacturers for many years.

FORGINGS

FORGINGS Forged Steel Business

- Forged Steel Used for Various Electrical Power plant

- We sell forged steel products used in a variety of electrical power-energy sources, including thermal, nuclear, and hydro-power generation. In thermal power generation, we have delivered a very large number of products such as generator shafts, turbine rotors, control valves, and casings and the like, for nuclear power generation we have delivered piping and storage cask components and the like, and for hydro-power generation we have delivered water turbine shafts and generator shafts and others.

- Strip Mill (Coarse, Intermediate, Finish Stand)

- We produce rolls with unique components that meet the characteristics required for each stand of a strip mill. We implement research and development so that we are able flexibly to respond to customer challenges, and we offer a variety of materials.

- Straightener Roller

- The straightener roller developed through our unique manufacturing technique exerts a cold hardening effect on the surface touching the product to be correct it by pouring hot water into the mold in the same shape as the product. The phenomenon effect between the complete crystals of the chilled layer and the crystal direction is adequately generated, and the dense matrix improves wear resistance and beautifies the skin of the corrected product. This technology is highly regarded by many users in Japan and abroad.